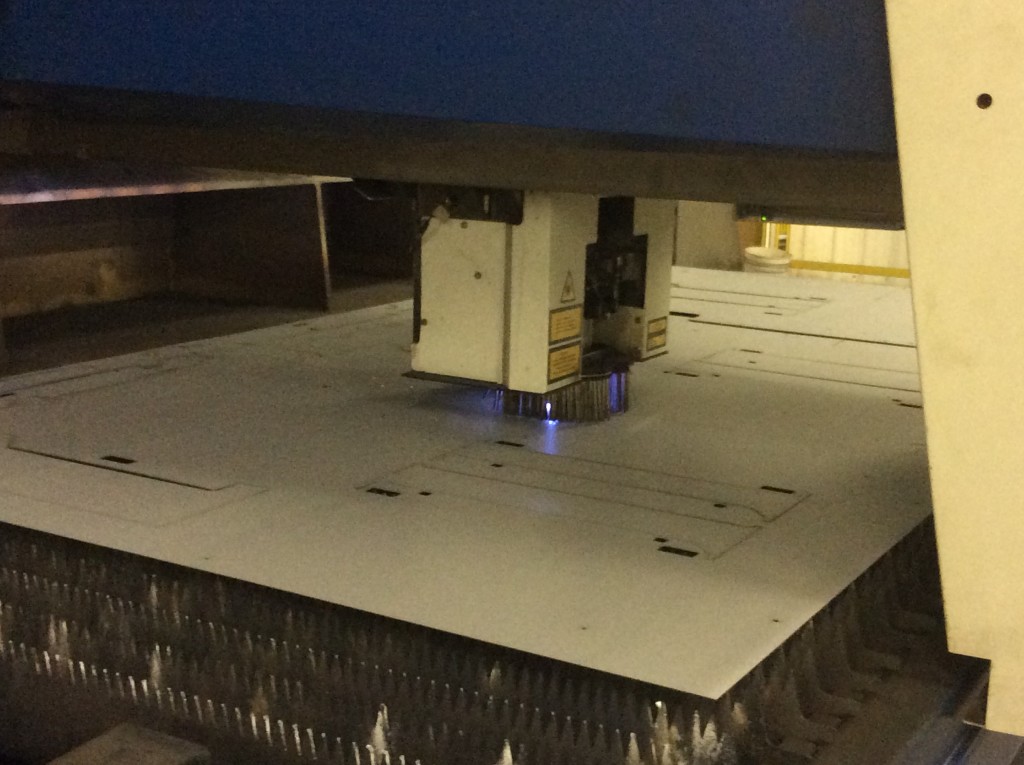

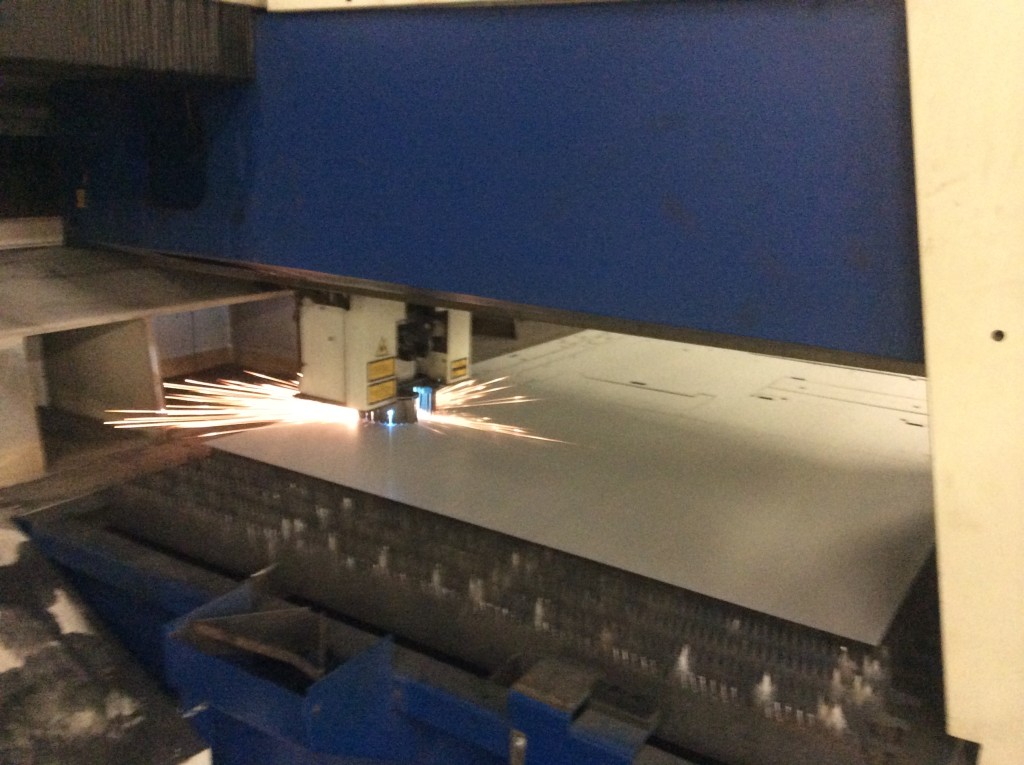

Laser cutting is a significant part of BCL precision metal fabrication business. Various CNC Laser cutting equipment will generate parts in a 5’ x 10’ envelope.

With our TRUMPF TruLaser cutters, we can offer the right solution for any application. These 5 foot by 10 foot flat sheet laser cutters enable an unparalleled mix of speed, versatility and simplicity. These compact machines come with a standard pallet changer with a number of advanced automation options.

Our Equipment

BCL has purchased a Trumpf next generation fiber optic laser. It will be delivered and installed third quarter of 2016.

The TruLaser 3030 fiber boasts of high flexibility and profitability: In particular it cuts mild steel with profitably at all sheet thicknesses. The TruDisk 3001 solid-state laser enables the processing of non-ferrous metals and, in addition, provides you with an extra productivity benefit when it comes to thin sheets. Proven functions such as the automatic nozzle changer provide for minimum downtimes.

-

Profitable mild steel processing at all sheet thicknesses

-

High flexibility due to processing of tubes and of non-ferrous metals

-

Production advantages in the thin-sheet range

-

The one-cutting-head strategy and automatic nozzle changer result in minimized downtimes

-

Maximum energy efficiency

TruLaser 3030 fiber Working range

X axis :120″

Y axis: 60″

Z axis: 4.5″

Max. material thickness with TruDisk 4001

Mild steel: .75″/1″

Stainless steel: .75″

Aluminium: .75″

Copper: 5/16″

Brass: 5/16″

Max. axis speed simultaneous

460ft/min

Dimensions

Length: 366″

Width: 200″

Height: 95″

Weight: 26,000 lbs

Flexibility

-

Sheet thicknesses of up to .98″ can be cut

-

Greater variety of material: The cutting of copper and brass with TRUMPF cutting data

-

Problem-free processing of sheets with film coating without previous vaporizing

-

Option of converting flat metal to tube processing with the RotoLas accessory

Productivity

-

The one-cutting-head strategy with collision protection and automatic nozzle changer result in minimized downtimes

-

Higher machine dynamics due to direct drive

-

Productivity advantage with thin sheets thanks to the TruDisk solid-state laser

-

Fast and efficient post-production and efficient utilization of remainder sheets thanks to the Drop&Cut function

-

High throughput and high process reliability due to intelligent functions

Quality

-

High-quality results in thick sheet metal thanks to the BrightLine fiber option

Operator friendliness

-

Good view within the machine with total laser safety

-

Ergonomic control panel with graphic user interface and self-explaining touch function operation

-

Simple maintenance and internal cleaning possible because of easy accessibility

Efficiency +

-

High-quality results in thick sheet metal thanks to the BrightLine fiber option

Our TruLaser 5030 / 5040 / 5060 high-end flatbed laser machine guarantees high productivity and efficiency.

This is ensured by the one-cutting-head strategy as well as the high process stability. Many different automation options and other smart operating features ensure outstanding results in continuous operation.

-

High productivity

-

Enormous joint speed and positioning dynamics

-

Excellent energy balance thanks to the world’s most efficient CO2 laser

-

Maximum process reliability in unmanned operation thanks to the Smart Nozzle Automation option

-

Cut edges of the highest quality throughout the whole machining spectrum

Working Range

X axis: 120 in.

Y axis: 60 in.

Z axis: 4.5 in.

Max Material Thickness with TruFlow 5000

Mild Steel: .75″

Stainless Steel: .50″

Aluminum: .50″

Max axis speed simultaneous

Length: 390″

Width: 180″

Height: 95″

Weight: 26,000lbs

Productivity

-

Minimized non-productive time thanks to the one-cutting-head strategy and optional nozzle changer

-

Reduced positioning times through simultaneous displacement of cutting heads

-

Reliable end-to-end processing thanks to the Smart Nozzle Automation option

-

Modular automation options

-

Intuitive operating concept

-

Mobile operation and monitoring of the machine using the MobileControl App

Quality

-

Precise contour cutting due to stable machine concept

-

High-performance CO2 cutting optics guarantees best-quality sheet metal parts of all thicknesses

-

Consistent quality throughout the working zone due to the fixed beam length

Flexibility

-

Sheets up to 50 mm thick can be processed

-

Different outputs for diverse processing tasks because of various beam sources

-

Support when processing materials and sheet thicknesses that require special treatment through innovative functions, such as CoolLine

efficiency+

-

Excellent energy balance thanks to the world’s most efficient CO2 laser

-

Reduced power consumption by more than 9,000 kWh per year due to the enhanced chillers in the laser cutting machines

-

Optimized standby mode of the TruFlow laser for reduced power consumption by up to 40 percent in processing preparation time

-

Highly precise beam guidance enables metal parts to be cut using the smallest of nozzle diameters and consequently with minimal gas consumption

-

Low-scratch processing and thus a minimum of scrap thanks to the concept of “flying optic”