• Surface machining or deburring of workpieces up to 120 mm sheet metal thickness

• Freely configurable – individually customised to the customer’s requirement

• High quality surface finish up to fine grinding

• Simultaneous deburring of interior and exterior contours

• Wet machining

• Simple, intuitive operation

• The processing units can be individually adjusted or turned on and off electrically.

• Maximum productivity while maintaining machining quality

• Faster and simpler tool change within just a few minutes

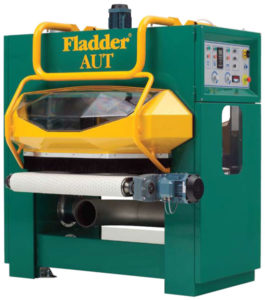

• Modular and compact in modern machine design – smaller footprint

• Improved work environment – Reduction of dust, dirt and noise

• Optionally available: Conveyor Technology, Filter Technology; Handling Systems, Automation; Custom Solutions

• Especially suitable for the material mix

• Entire process lines – Grinding and Part Cleaning